Arena Footing Basics 101- Part II

Martin Collins

Equestrians will agree, when it comes to arena riding, a well-appointed ring is a joy to work (and play!) in. The footing you choose for your enclosure will depend on a variety of factors and will be the most important component of a well-designed and properly constructed riding area. In the second of this two-part article, Glynnie Walford of Martin Collins© Equine Surfaces provides the information you need to create a first-rate surface for all of your equine endeavors.

Choosing the Right Surface

Well-kept turf is the ideal surface for training and equestrian competitions; it is the traditional footing for all equestrian sports. However, in situations where turf cannot be sustained, all-weather surfaces for horses allow them to train and compete in different situations and weather conditions.

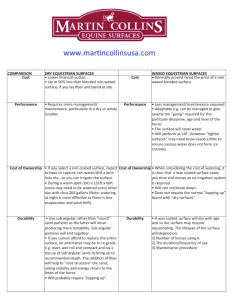

There are six main types of surfaces for horses available in the U.S. – fibers, sand/ mix, dirt, wood products, rubber, and wax-coated (often referred to as all-weather). These days, PVC and rubber are less popular choices as they tend to “ride deep” in dry periods and disposal legislation is becoming restrictive; so structural fibers are becoming the norm.

* Wax-Coated Equestrian Surfaces

Wax-coated equestrian surfaces will give you the closest equivalent to turf, without the need for “managed rain fall.”

* Dry, Sand-Based Surfaces

Dry, sand-based surfaces refer to equestrian surfaces made up of sand, mixed or topped with another material such as rubber or synthetic fibers. This addition of fibers to sand is becoming the most commonly used equestrian surface of the 21st century.

Upgrading Your Arena Surface

Extreme weather conditions inevitably put added pressure on your arena surface. Common problems are that surfaces become either too firm or too deep, and – in the case of sand-based surfaces – dry and dusty. If your surface is suffering, don’t automatically assume that it’s a case of facing the expense of entire replacement.

A complete overhaul is not always necessary (and certainly not always within an individual’s budget). Consider, instead surface enhancement, or refurbishment.

Replacing the whole surface is, of course always an option. However, it is advisable to verify the condition of the underlying base. If the base is in need of remedial work this should be done before any replacement of surface, otherwise you will only be ‘throwing good money after bad!

Care and Maintenance of Your Surface

The amount and type of arena grooming often depends on what type of surface you have. Some of the ‘dry’ surfaces require more water or grooming than others.

* Wax-coated

Wax-coated riding surfaces are dust free (providing the maintenance procedure is adhered to) and have a very good climactic tolerance and do not require an irrigation system. It is worth noting that Martin Collins synthetic horse riding surfaces are NOT coated with oils or petroleum jellies for two important reasons:

- Some oils can wash through the surface and render the underlying base impervious. They are susceptible to melting in the warmer weather causing inconsistent ‘going.’

- Neither oils nor petroleum jellies have the same lifespan as a wax-coated surface and will therefore require re-coating much sooner.

* Non-Coated

Non-coated riding surfaces require more maintenance than those with a wax coating. For optimum performance, an irrigation system is essential. Once a surface has dried out it can ride “deep” and can quickly become un-level. However, this can be rectified with specialized machinery.

Care Advice For All Synthetic Riding Surfaces

Martin Collins surfaces are sold to provide an average COMPACTED depth of approximately 4” when laid. Some others are sold UNCOMPACTED so, when laid, the depth can be reduced by 2″ (50mm). The following advice applies to all surfaces.

It is important that your new surface is kept both level and evenly compacted. If any hollows, dips or tracking appear, these should be corrected by hand raking prior to grooming the surface.

It is advisable to provide a clean approach to the arena to prevent both horses and maintenance equipment from bringing debris onto the footing and contaminating it.

Fences should be moved frequently, and takeoff and landing pads hand raked before the stands are put away.

Making Your Riding Surface Last

The life span of a correctly installed and high performance riding surface will be determined by a range of factors. To protect your investment:

- Follow the manufacturer’s recommended maintenance guidelines.

- Lift all debris, horse droppings, leaf fall, etc.

- Carry out regular depth checks; these will immediately flag “dangerous” inconsistencies in overall depth i.e. 2” – 6.”

- Construct a track to the arena to keep horses’ feet and maintenance equipment clean when entering the arena.

The Size of the School

If you have a very small school, you may find the surface wears a little more quickly, as the horses are working “on the turn.”

There is more pressure on the footing on turns, so lay additional depth for safety. The footing provider should assist and recommend the depth in such instances.

In Closing…

The above information is intended as a guide for those planning/ constructing a new riding surface or upgrading a pre-existing one. Remember, a thoughtful investment of time and finances now will ensure less time spent worrying about your arena – and more time enjoying it – for years to come.

North America’s premier equestrian footing experts, Martin Collins USA, have provided this important guide on arena material selection and construction.

About the author:

Glynnie Walford has been with the Martin Collins Group for 23 years and has extensive knowledge across the sports horse and thoroughbred racing worlds having been actively involved in both. She was CEO of the British based company before relocating in 2010 to promote the company and its products in the USA.

Glynnie has coached the British Dressage Regional Advisors on footing and has spoken at the Aachen School of Course Design in Germany. Glynnie was formerly a dressage competitor and work rider for Thoroughbred trainers. She now has a keen interest in the cutting world and has Quarter Horses. Thinking about building a new arena or just have questions about your current footing? Visit martincollinsusa.com and complete the contact form.